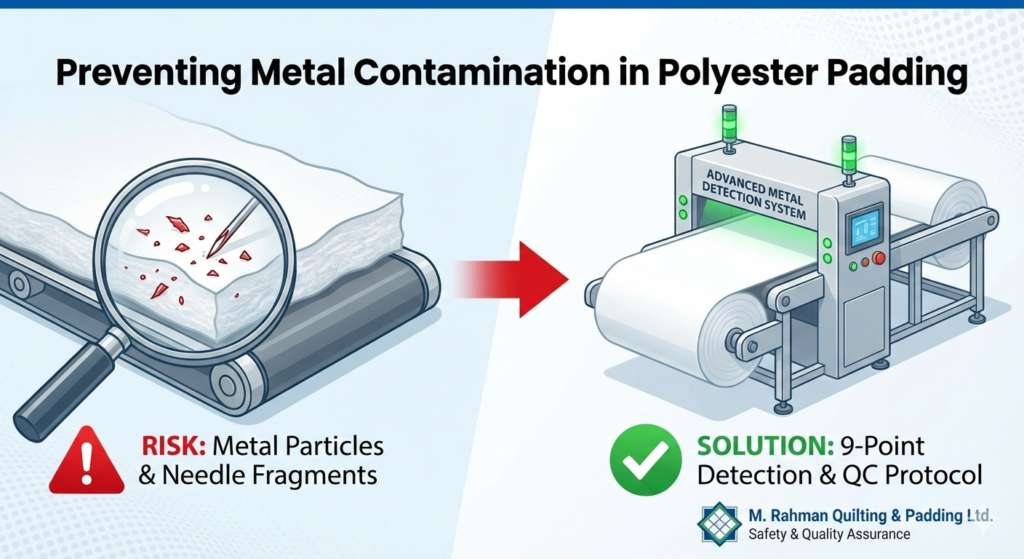

In the global textile manufacturing industry, safety is just as important as comfort. One of the most critical yet common challenges faced by manufacturers is the presence of metal particles in polyester padding. For international apparel brands, a single stray needle fragment can lead to massive product recalls, legal liabilities, and a damaged brand reputation.

At M. Rahman Quilting & Padding Ltd., we prioritize garment safety standards by implementing a rigorous broken needle policy and advanced detection technology to ensure our products are 100% contamination-free.

Why Do Metal Particles Occur in Polyester Padding?

Metal contamination typically happens during the manufacturing process due to:

- Needle Breakage: High-speed quilting machines or carding equipment can occasionally break, leaving microscopic fragments inside the high-loft padding.

- Raw Material Contamination: Impurities in low-quality polyester staple fiber sourced from unverified suppliers.

- Mechanical Wear: Small shavings from industrial machinery during the thermobonding process.

The Risk: Why Metal Detection is Non-Negotiable

For manufacturers of puffer jackets, sleeping bags, and baby wear, “Metal-Free” is a mandatory requirement. If a metal particle is found in a finished garment:

- Safety Hazards: It poses a direct physical risk to the end consumer.

- Export Rejections: Shipments to Europe and the USA must pass through a needle detector machine. Any failure results in the entire batch being rejected.

- Compliance Failure: Standards like Oekotex-100 and RCS demand strict adherence to safety and purity.

M. Rahman’s Solution: Advanced 9-Point Metal Detection

As a leading padding manufacturer in Bangladesh, we have invested in state-of-the-art machinery to eliminate this problem. Our padding unit in Gazipur follows a multi-step safety protocol:

1. High-Sensitivity Industrial Metal Detectors

Every yard of our polyester wadding and synthetic down filling passes through high-sensitivity needle detector machines. These sensors can identify ferrous particles as small as 0.8mm, ensuring absolute purity.

2. Strict Broken Needle Policy

We maintain a documented broken needle policy. If a needle breaks in our computerized quilting unit, production stops immediately until every fragment is accounted for and matched to the broken piece.

3. Quality Control (QC) at Every Stage

From the initial carding process to the final roll of Down Touch padding, our QC team performs random “pull tests” and secondary scans. This meticulous attention to detail is why we are the preferred partner for high-end export-quality padding.

Conclusion: Trust M. Rahman for Safe, High-Performance Insulation

Don’t let metal contamination ruin your production. By choosing M. Rahman Quilting & Padding Ltd., you are partnering with a factory that understands the complexities of global safety compliance. We combine high-capacity output with the most reliable safety protocols in the Gazipur textile hub.

Are you looking for 100% metal-free, Oekotex-certified padding? [Contact our experts today] to learn more about our safety standards and how we can help you reduce garment production costs without compromising on safety.