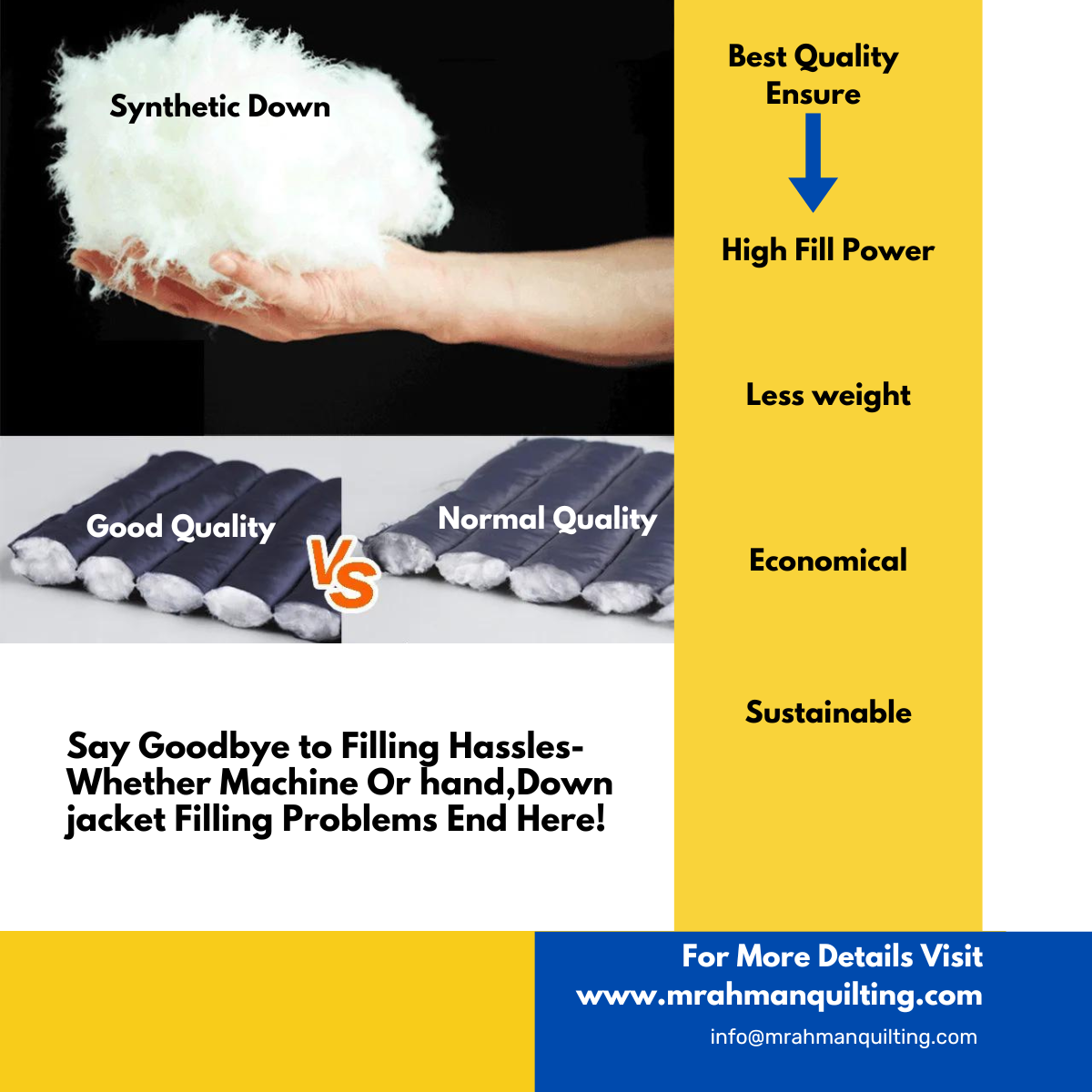

In the modern garment manufacturing industry, synthetic down (also known as fake down or ball down) has become the go-to insulation for high-performance puffer jackets. However, many factories face recurring production nightmares: fiber entanglement, filling pipe blockage, and low fill power that leads to heavy, unappealing garments.

At M. Rahman Quilting & Padding Ltd., we have engineered the solution. By understanding the science of microfiber insulation, we help manufacturers reduce waste and improve production speed.

Common Problems in Synthetic Down Filling

Whether you are using automated machines or manual stuffing, these issues can derail your production timeline and increase costs:

- Low Fill Power: When fiber lacks “loft,” you need to use more material to fill the same space, directly increasing your garment production costs.

- Pipe Blockage: Poorly cut fibers often clump together, causing downtime in automated filling machines.

- Entanglement: Fibers that aren’t properly siliconized become knotted, resulting in a lumpy, uneven finish on the jacket.

The Technical Solution: Microfiber Engineering

To achieve the perfect “down-like” feel, the technical specifications of the fiber must be precise. Our R&D team at MRQP Ltd. recommends the following standards:

1. Denier and Fineness

For maximum softness and insulation, use super-soft microfiber with a fineness below one denier. We specifically recommend 0.9D (denier) to mimic the lightweight properties of natural goose down.

2. Optimized Cut Lengths

The secret to a smooth filling process lies in the cut length. Using the wrong length leads to machine failure or poor hand-stuffing density:

- Machine Filling: 0.9D x 25MM is the ideal specification to prevent pipe blockage and ensure a smooth flow.

- Hand Filling: 0.9D x 32MM provides better grip and distribution for manual stuffing.

3. The Silicone Factor

High-quality synthetic down must be properly treated with high-grade silicone during production. Siliconized fibers reduce friction, preventing entanglement and ensuring the jacket remains super soft and “fluffy” even after multiple washes.

Maximize Loft with Sustainable Synthetic Down

As a sustainable textile manufacturer in Bangladesh, M. Rahman Quilting & Padding Ltd. produces Oekotex and RCS-certified synthetic down. Our high-loft fibers are designed to trap more air with less weight, giving your jackets higher thermal insulation values while using less raw material.

Why Partner with M. Rahman Quilting & Padding Ltd.?

- Reduced Fiber Consumption: High fill power means you use less fiber per jacket.

- Zero Downtime: Precision-cut lengths specifically for machine filling.

- Global Compliance: We adhere to the strictest environmental and safety standards.

Conclusion: Say Goodbye to Filing Hassles

Don’t let technical filling problems affect your bottom line. Transitioning to specialized 0.9D microfiber with optimized cut lengths will transform your production efficiency.

Ready to upgrade your jacket production? [Contact M. Rahman Quilting & Padding Ltd. today] for the highest quality synthetic down filling solutions in Bangladesh.